What is a gravity roller conveyor?

A gravity conveyor is an unpowered chute or roller which uses the force of gravity to propel materials on a downward trajectory. Standard gravity conveyors are typically used to transport materials or items with enough weight to allow them to move downhill without assistance. These conveyors can be useful on construction sites to removing debris.

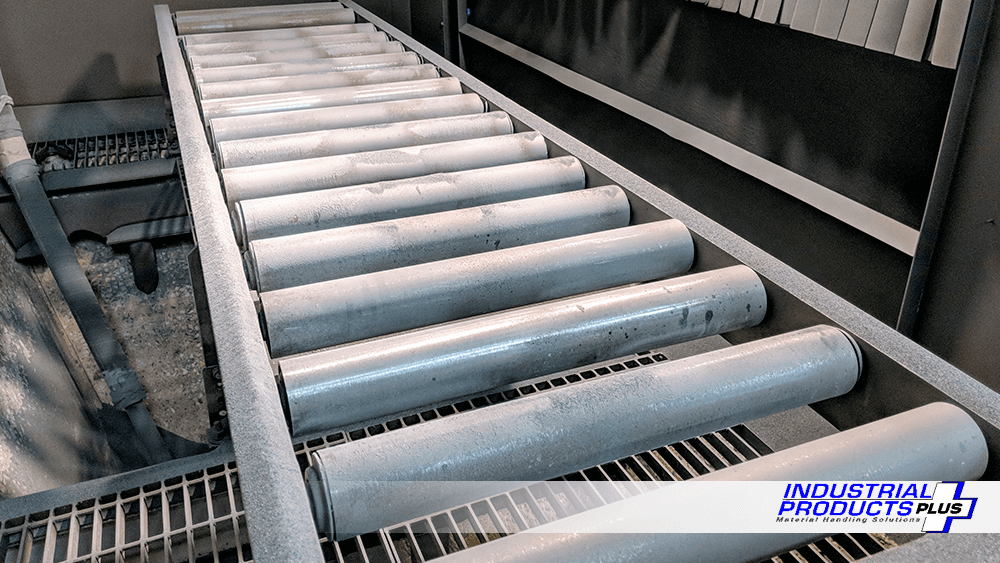

Gravity roller conveyors involve fabricated frameworks constructed in longitudinal sections. Rotating tubular rollers are placed atop these fabrications to allow for the movement of items. These gravity rollers are often used to move cartons, boxes, totes, and other items with rigid bottoms in warehouses and factories.

Spacing between rollers or skate wheels can vary depending on the purpose of the gravity roller conveyor. As a rule of thumb, a minimum of three rollers should always be under the item being moved, in order to provide sufficient momentum.

Why choose a gravity roller conveyor?

Gravity conveyors and gravity roller conveyors are incredibly economical. They’re also versatile, as they can be moved and reconstructed depending on the requirements of your organization. They are the most common form of conveyor in the world of commerce, and can be used for a variety of purposes, including the following:

- Loading/unloading of delivery trucks

- Conveyance in picking/packing areas

- Delivering items on assembly lines

- Mounting to scales, carts and other industrial machinery

Gravity roller conveyor features

Some models are extendable, which makes them flexible for various tasks. Gravity roller sections can even be linked together as a means to load/unload a vehicle when the vehicle is unable to enter a standard loading dock (for example, if a large articulated lorry can’t fit in the loading bay of a small warehouse). In some instances, businesses require telescopic gravity roller conveyors that taper in at the bottom. This allows for the smooth and regular movement of products on a “one-by-one” basis, which is particularly useful for pickers and packers at the end of the conveyor.

Gravity roller conveyor manufacturers often mount their products on castors to allow for convenient movement. These castors can be locked using a braking system to allow for sturdiness when required.

Gravity conveyor finishes

Light duty gravity conveyors are perfect for handling and distribution. They are available in a variety of finishes, depending on the applications of the conveyor within your business. Steel rollers are available in aluminum, stainless steel, BZP, and PVC finishes, while the side frames can be constructed from stainless steel, aluminum, or wood.

If you would like to know more about how a gravity roller conveyor could benefit your organization, please do not hesitate to get in touch with us today. A member of our friendly and experienced team will be more than happy to discuss your requirements and recommend the best products based on the information you provide us.