10 Things Not to Do with Your Warehouse Racks: A Comprehensive Guide to Pallet Rack Safety

Introduction

In the realm of modern logistics and industrial storage, the significance of pallet rack safety cannot be overstated. At Industrial Products Plus, we understand the pivotal role that warehouse racks play in businesses not only in Costa Mesa, CA, but also throughout the global supply chain. These robust storage systems serve as the backbone of efficient warehouse management, facilitating the optimization of space utilization, the streamlining of inventory processes, and, most importantly, the assurance of pallet rack safety. However, to truly harness the potential of your warehouse racks, it’s imperative to navigate skillfully around common pitfalls that could compromise safety, efficiency, and longevity.

1. Overloading the Racks: Why It’s a Big No-No

In the intricate web of pallet rack safety considerations, the specter of overloading looms large as an unforgivable misstep. Overloading your warehouse racks represents not just a common error but one with potentially catastrophic consequences. The excessive weight placed upon these storage systems can lead to racks buckling or, in the worst-case scenario, collapsing entirely. Such an eventuality poses an immediate and severe threat to the well-being of your employees and also jeopardizes the integrity of your valuable inventory. In the pursuit of pallet rack safety, there are two fundamental pillars that must be upheld: strict adherence to weight limits specified by the manufacturer and a meticulous focus on proper weight distribution within your storage racks warehouse.

Adhering to weight limits is the cornerstone of pallet rack safety. Manufacturers meticulously engineer their rack systems with specific weight-bearing capacities in mind. These limits are not mere suggestions but rather precise calculations based on the materials used and the structural design. Exceeding these limits places an immense strain on the racks, and they can only bear so much before giving way. The consequences of overloading are dire, ranging from immediate rack failure to gradual structural damage that may go unnoticed until it’s too late.

Furthermore, maintaining proper weight distribution within your storage racks warehouse is an equally critical aspect of pallet rack safety. Uneven distribution can create localized stress points, increasing the risk of structural failure. Ensure that heavy items are placed on lower levels, evenly distributed across beams, and that lighter items are stored at higher levels. This not only safeguards pallet rack safety but also enhances overall efficiency in accessing and managing inventory.

2. Neglecting Regular Inspections and Maintenance

The longevity and safety of your warehouse racks hinge on a regimen of regular inspections and maintenance. Neglecting these fundamental tasks can set the stage for unnoticed damage and wear and tear, ultimately culminating in rack failure and a compromised pallet rack safety.

Inspecting your racks regularly is akin to a vigilant guardian overseeing the well-being of your storage systems. This practice involves scrutinizing racks for signs of damage, rust, or misalignment. Timely identification of these issues is crucial to maintaining the structural integrity of your racks and preserving pallet rack safety. A visual inspection can often reveal cracks, bent beams, or signs of corrosion that may not be immediately apparent but could lead to catastrophic failures if left unaddressed.

In addition to visual inspections, routine maintenance is a vital aspect of pallet rack safety. This entails tasks such as tightening bolts, repairing or replacing damaged components, and addressing rust or corrosion. Neglecting these maintenance activities can lead to gradual deterioration, weakening the structural integrity of the racks over time. Overlooking even seemingly minor issues can have far-reaching consequences for pallet rack safety.

3. Incorrect Installation and Improper Use of Racks

The foundation upon which pallet rack safety rests is the correct installation of your warehouse racks. Conversely, incorrect installation and improper use represent grave mistakes that can compromise the integrity of your racks and, consequently, pallet rack safety.

Warehouse rack manufacturers provide precise guidelines for the installation of their products. These guidelines are meticulously crafted to ensure the structural stability and safety of the racks. Deviating from these guidelines or cutting corners during installation can have dire consequences. When racks are improperly installed, they lack the structural integrity necessary to withstand the loads they are designed to bear. This not only endangers pallet rack safety but also puts your entire inventory and operational efficiency at risk.

Equally critical is the proper use of warehouse racks. Educating your staff on the correct usage of racks is a vital aspect of pallet rack safety. Mishandling, misuse, or disregard for established safety protocols can lead to accidents, damage to inventory, and even structural failures. Your employees must understand the importance of adhering to safety guidelines and using the racks in the manner intended by the manufacturer.

4. Ignoring Safety Precautions and Guidelines

Within the dynamic environment of a warehouse, safety should always reign supreme. Ignoring safety precautions and guidelines can result in preventable accidents and injuries, which, in turn, can compromise pallet rack safety.

To uphold pallet rack safety, it is imperative to implement robust safety measures within your warehouse. These measures include clear signage, unobstructed aisleways, and the installation of safety barriers within your racks warehouse.

Clear signage serves as a constant reminder to your employees of safety protocols and guidelines. It ensures that everyone in your warehouse is aware of potential hazards and the proper procedures to mitigate them. Signage can indicate weight limits, offer instructions for proper loading and unloading, and highlight areas where caution is required.

Unobstructed aisleways are essential for maintaining pallet rack safety. They provide a clear path for personnel and equipment, reducing the risk of accidents caused by congestion or impediments. A clutter-free workspace not only enhances safety but also promotes efficiency.

Safety barriers serve as protective shields, shielding both your employees and your inventory from accidents. These barriers can prevent collisions with racks, machinery, or other obstacles within your warehouse. By installing these barriers strategically, you create a safer warehouse environment that upholds pallet rack safety.

5. Storing Incompatible or Hazardous Materials on the Racks

One of the gravest threats to pallet rack safety is the storage of incompatible or hazardous materials on your warehouse racks. This practice can lead to chemical reactions or material incompatibility, posing significant safety risks to your employees and the integrity of your inventory.

To mitigate these risks and ensure pallet rack safety, it is imperative to categorize and store materials appropriately, following safety guidelines and regulations when utilizing storage racks within your warehouse.

Segregating hazardous materials is paramount for pallet rack safety. Chemicals, substances, or materials that have the potential for adverse reactions should be stored separately and according to the manufacturer’s recommendations. This prevents unintended interactions that could result in fires, explosions, or the release of toxic gases.

Proper ventilation is another essential aspect of pallet rack safety when storing hazardous materials. Adequate airflow helps dissipate potentially harmful fumes or gases, reducing the risk of accidents or health hazards. Proper ventilation systems should be installed in areas where hazardous materials are stored.

In addition to these measures, implementing safety features such as spill containment systems further safeguards pallet rack safety. These systems are designed to capture and contain spills, preventing them from spreading and causing more extensive damage.

6. Failing to Organize and Label the Racks Properly

Disorganization within your warehouse can have far-reaching consequences, directly impacting both efficiency and pallet rack safety. Failing to label and organize racks for warehouse storage properly can result in wasted time and effort when searching for items, reducing overall efficiency and potentially compromising pallet rack safety.

To optimize both storage space and workflow while enhancing pallet rack safety, it is imperative to implement a systematic labeling system and organize your racks logically.

A systematic labeling system ensures that items are easily identifiable and accessible. It streamlines the process of locating specific items within your racks, reducing the risk of accidents caused by misplaced items. Each rack or storage location should be clearly labeled with information about the contents, including SKU numbers, product descriptions, and any relevant safety information.

Organizing racks logically is equally critical for pallet rack safety and operational efficiency. Heavy items should be stored on lower levels, evenly distributed across beams, while lighter items should be stored at higher levels. This not only minimizes the risk of accidents caused by unbalanced loads but also facilitates ease of access during loading and retrieval.

7. Not Utilizing Rack Accessories and Safety Features

Many warehouse racks come equipped with accessories and safety features specifically designed to improve functionality and safety, thereby enhancing pallet rack safety. Neglecting to use these additions can limit the efficiency of your racks and compromise overall safety.

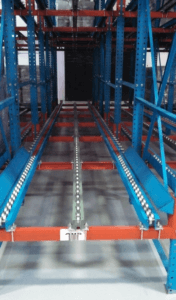

To bolster pallet rack safety, it is crucial to explore and utilize options such as dividers, guards, and anti-collapse systems to enhance your rack setup within your storage racks warehouse.

Dividers serve as valuable tools for maintaining pallet rack safety. They prevent items from falling or spilling over, reducing the risk of accidents and damage to inventory. By partitioning storage areas, dividers ensure that items are securely contained, even in high-density storage environments.

Guards are another essential safety feature that can prevent accidents and protect both employees and inventory. Rack guards can be strategically placed to shield racks from collisions with forklifts, pallet jacks, or other equipment. These guards absorb impact, minimizing the risk of structural damage and preserving pallet rack safety.

Anti-collapse systems provide additional structural support to prevent potential collapses, further bolstering pallet rack safety. These systems are particularly valuable in high-traffic areas or environments where the risk of impact is elevated. By reinforcing the integrity of your racks, anti-collapse systems enhance the safety and stability of your storage systems.

8. Ignoring Employee Training and Awareness on Rack Usage

The role of your employees in pallet rack safety cannot be overstated. Ignoring proper training and awareness programs can lead to mishandling, accidents, and damage to inventory. To ensure that your team actively contributes to pallet rack safety, it is imperative to provide comprehensive training on rack usage, safety protocols, and emergency procedures.

Proper training is the foundation upon which pallet rack safety knowledge is built. It equips your employees with the skills and understanding required to use warehouse racks safely and effectively. Training should cover topics such as proper loading and unloading techniques, weight distribution, and how to identify and report potential safety hazards.

Safety protocols are equally vital components of pallet rack safety. Your employees must be aware of established safety guidelines and adhere to them rigorously. These protocols encompass aspects such as weight limits, clearance zones, and safe handling practices.

Emergency procedures provide a roadmap for responding to unforeseen situations. In the event of an accident or structural failure, your employees should be well-prepared to react swiftly and efficiently to mitigate the impact on pallet rack safety. This includes knowledge of evacuation procedures, communication protocols, and how to access emergency equipment such as fire extinguishers and first-aid kits.

Fostering a culture of safety awareness among your employees is the final piece of the puzzle for pallet rack safety. Encouraging your team to actively identify and report potential safety hazards contributes to a proactive approach to safety. This can include regular safety meetings, open communication channels for reporting concerns, and incentives for promoting safety.

9. Neglecting Rack Load Capacity Labels and Documentation

Neglecting to pay attention to rack load capacity labels and documentation is a critical oversight that can jeopardize pallet rack safety. Load capacity labels and documentation provided by the manufacturer are invaluable resources for understanding the limitations and capabilities of your warehouse racks.

Load capacity labels typically display essential information such as the maximum weight each shelf or beam can support, as well as the overall capacity of the entire rack system. These labels are not mere decorations but vital guidelines that should be respected at all times. Failing to adhere to these weight limits can lead to overloading, which we discussed earlier as a cardinal sin in pallet rack safety. Overloading racks can cause structural failures, risking the safety of your employees and the integrity of your inventory.

Additionally, manufacturer documentation often includes comprehensive guidelines and recommendations for safe usage and maintenance of your warehouse racks. This documentation may outline specific procedures for assembly, installation, and maintenance, ensuring pallet rack safety is upheld throughout the rack’s lifecycle.

To avoid this pitfall, always ensure that load capacity labels are clearly visible and legible on your warehouse racks. Educate your staff about the significance of these labels and the importance of adhering to weight limits. Regularly review and follow the manufacturer’s documentation for proper assembly, installation, and maintenance. By doing so, you reinforce pallet rack safety by respecting the manufacturer’s specifications and guidelines, ultimately contributing to the longevity and safety of your warehouse racks.

10. Neglecting Fire Safety Measures for Rack Storage

Neglecting fire safety measures within your rack storage area is a hazardous oversight that can have catastrophic consequences. Warehouses often store a wide range of inventory, some of which may be flammable or combustible. Ignoring fire safety precautions and failing to implement proper measures can result in devastating fires that not only endanger lives but also cause significant property damage.

To ensure pallet rack safety in relation to fire hazards, several key measures should be taken:

a. Fire Sprinkler Systems

One of the most critical fire safety measures is the installation of fire sprinkler systems within your warehouse. These systems can rapidly suppress and control fires, preventing them from spreading and causing extensive damage. It’s essential to ensure that your rack storage area is equipped with adequate sprinklers and that they are regularly inspected and maintained.

b. Proper Aisle Clearance

Maintaining adequate clearance between racks and ensuring unobstructed aisleways is vital for fire safety. This allows for the efficient movement of firefighting equipment and personnel in the event of a fire. Neglecting aisle clearance can impede the response to a fire emergency and hinder pallet rack safety.

c. Flammable Materials Storage

When storing flammable materials within your warehouse racks, it is crucial to follow strict safety guidelines. Flammable materials should be stored in designated areas equipped with fire-resistant storage solutions. Proper ventilation should be in place, and fire barriers or fire-resistant walls may be necessary to prevent the spread of flames.

d. Emergency Response Plan

Develop a comprehensive emergency response plan that includes procedures for evacuating personnel, notifying emergency services, and controlling the spread of fire. Regularly train your employees on these procedures to ensure they are well-prepared in the event of a fire emergency.

e. Fire Extinguishers

Strategically place fire extinguishers throughout your warehouse, particularly in areas where flammable materials are stored. Ensure that your employees are trained in the proper use of these extinguishers.

f. Smoke and Fire Detection Systems

Install smoke and fire detection systems to provide early warning in case of a fire. These systems can trigger alarms and sprinkler activation, helping to contain fires before they escalate.

Ignoring fire safety measures within your rack storage area is a grave oversight that can have devastating consequences. By diligently implementing these measures, you not only protect the safety of your employees but also safeguard your inventory and the structural integrity of your warehouse racks. Fire safety is a critical aspect of pallet rack safety that should never be underestimated or neglected.

Conclusion and the Importance of Proper Rack Management for a Safe and Efficient Warehouse

Industrial Products Plus leads in turnkey material handling solutions and industrial product sales, offering innovative solutions like industrial shelving, pallet racking, and modular office solutions. We prioritize customer satisfaction, maintain a loyal client base, and foster an empowering corporate culture. Contact us for a free quote today.

In conclusion, the proper management of warehouse racks is not just important but instrumental in maintaining pallet rack safety and ensuring an efficient warehouse environment. Avoiding common mistakes such as overloading, neglecting maintenance, and ignoring safety measures is paramount. By implementing best practices and prioritizing safety, your warehouse in Costa Mesa, CA, can operate smoothly, ensuring the protection of your employees and valuable inventory while maximizing efficiency.

A well-organized and safely managed warehouse, with the expertise of Industrial Products Plus, is the cornerstone of your business’s success and pallet rack safety. We understand that every aspect of your warehouse, from the initial installation of racks to daily maintenance and employee training, contributes to pallet rack safety. Our commitment to pallet rack safety and efficiency extends beyond mere product sales; we provide comprehensive solutions and expert guidance to ensure the highest standards of pallet rack safety are upheld in your facility. Contact us at (714) 641-8100 for more information, and let us be your partner in achieving a safe and efficient warehouse environment that sets the stage for your continued success. Call us at (714) 641-8100 for more information.

FAQs

FAQ 1: Why is Overloading Warehouse Racks a Safety Concern?

Q: What is the primary reason overloading warehouse racks is considered a safety concern?

A: Overloading warehouse racks is a significant safety concern because it can lead to catastrophic consequences. When racks are overloaded with excessive weight, they can buckle or even collapse, posing a severe threat to employees and causing substantial damage to valuable inventory. Adhering to weight limits specified by the manufacturer and ensuring proper weight distribution within your storage racks warehouse are crucial steps to safeguard against these dangers.

FAQ 2: How Can I Ensure Pallet Rack Safety in My Warehouse?

Q: What steps can I take to ensure pallet rack safety in my warehouse?

A: Ensuring pallet rack safety involves several key measures:

- Regularly inspect your racks for signs of damage, rust, or misalignment.

- Follow manufacturer guidelines and industry standards for proper installation and usage.

- Implement safety precautions, such as clear signage, unobstructed aisleways, and safety barriers.

- Store materials appropriately, following safety guidelines and regulations.

- Organize and label racks systematically to optimize storage space and workflow.

- Utilize rack accessories and safety features, such as dividers, guards, and anti-collapse systems.

- Provide comprehensive employee training and foster a culture of safety awareness.

FAQ 3: Why Should I Pay Attention to Fire Safety in Rack Storage?

Q: Why is fire safety important when it comes to rack storage in my warehouse?

A: Fire safety is crucial for rack storage because warehouses often contain flammable or combustible materials. Neglecting fire safety measures can lead to devastating fires that endanger lives and property. To enhance pallet rack safety in relation to fire hazards, install fire sprinkler systems, maintain proper aisle clearance, follow strict guidelines for storing flammable materials, develop an emergency response plan, place fire extinguishers strategically, and install smoke and fire detection systems. These measures are essential to protect your employees, inventory, and the structural integrity of your warehouse racks from the risks posed by fires.