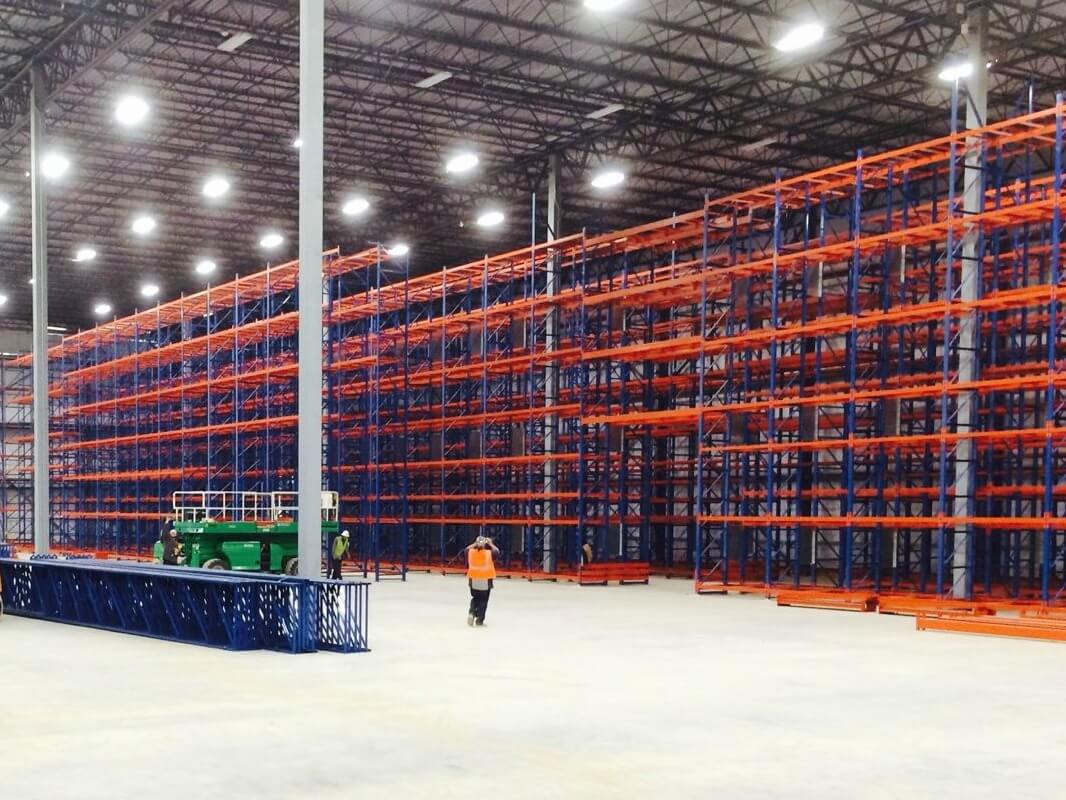

Industrial pallet Racking Solutions

Pallet Racking Solutions for Warehouse Storage and Material Handling

Store You Inventory Items efficiently with our Warehouse Pallet Racking Systems and custom solutions

We offer many types of Pallet Racking Systems and provide only the most appropriate solutions based on your current needs. With us, you can plan out, design, and order your specific solution and have every warehouse pallet racking system delivered and installed with efficiency while meeting your timetable and budget.

Types of Pallet Racking storage systems available:

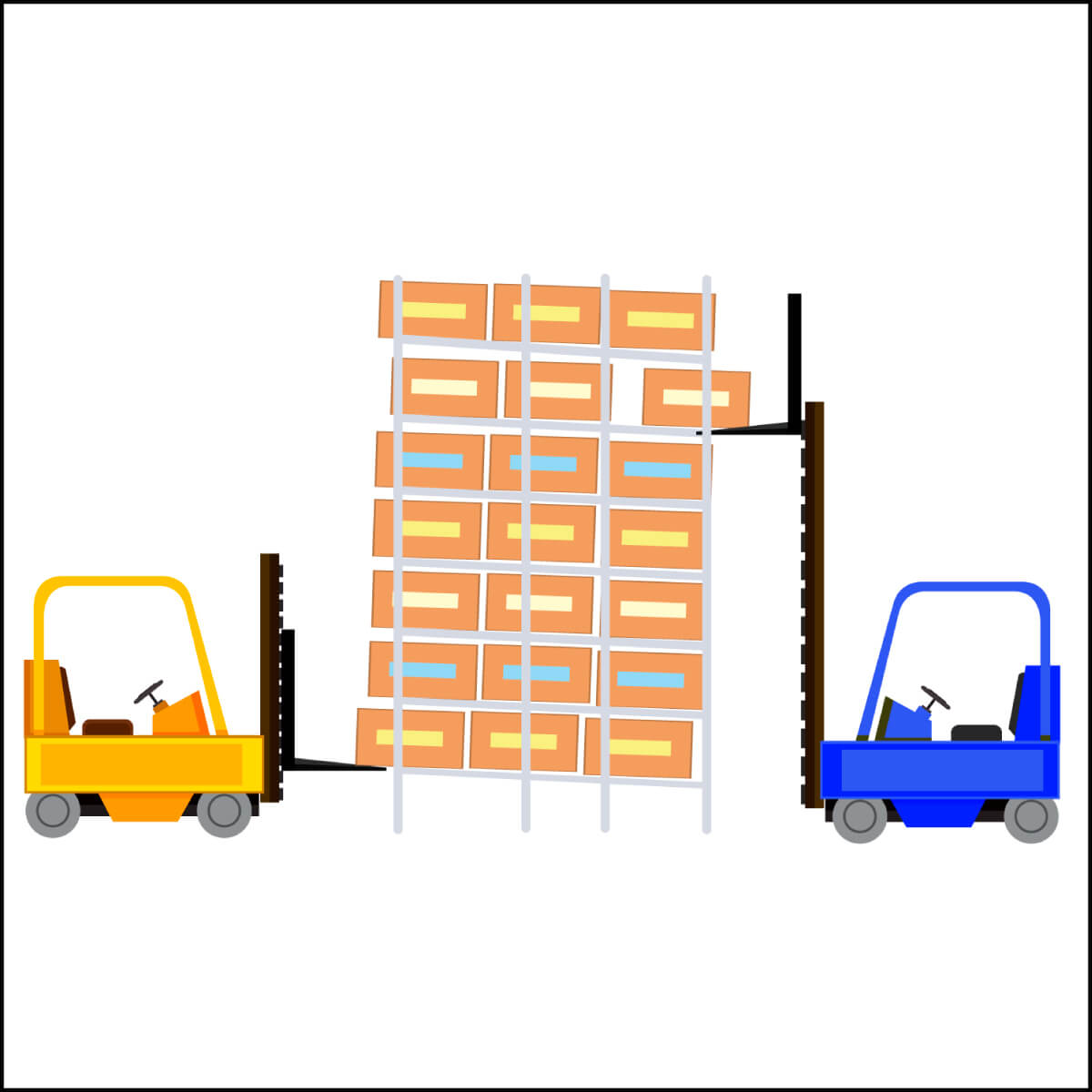

Selective Pallet Racks

Selective pallet racks are the most commonly used pallet storage system in the world. Their versatility provides 100% access to every pallet of products or merchandise within the system.

Because of the multiple aisle requirements, these selective racks sacrifice floor space, which results in lower storage density. However, for faster-moving products and the best retrieval, a selective rack storage system is the ideal choice.

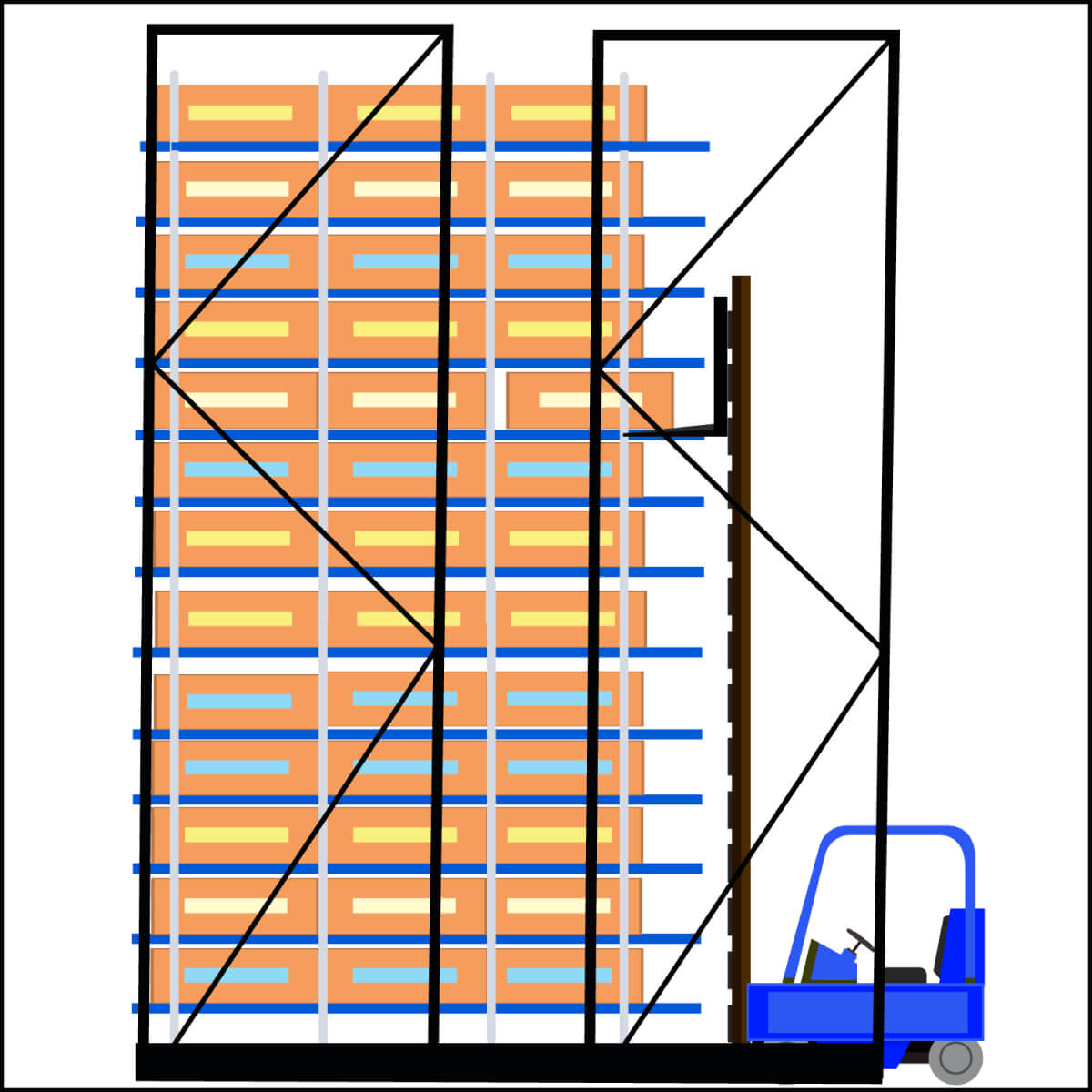

Multi-level Rack Pick module

Pick modules are high-density Storage and Picking Systems. Typical applications are multi-level and utilize a first-in/first-out rotation of pallets and/or cartons by using gravity flow to bring a product from the stocking aisle to the picking aisle.

This type of storage increases full case and/or split case order picking productivity by minimizing the walking distance between items picked and maximizes valuable warehouse space.

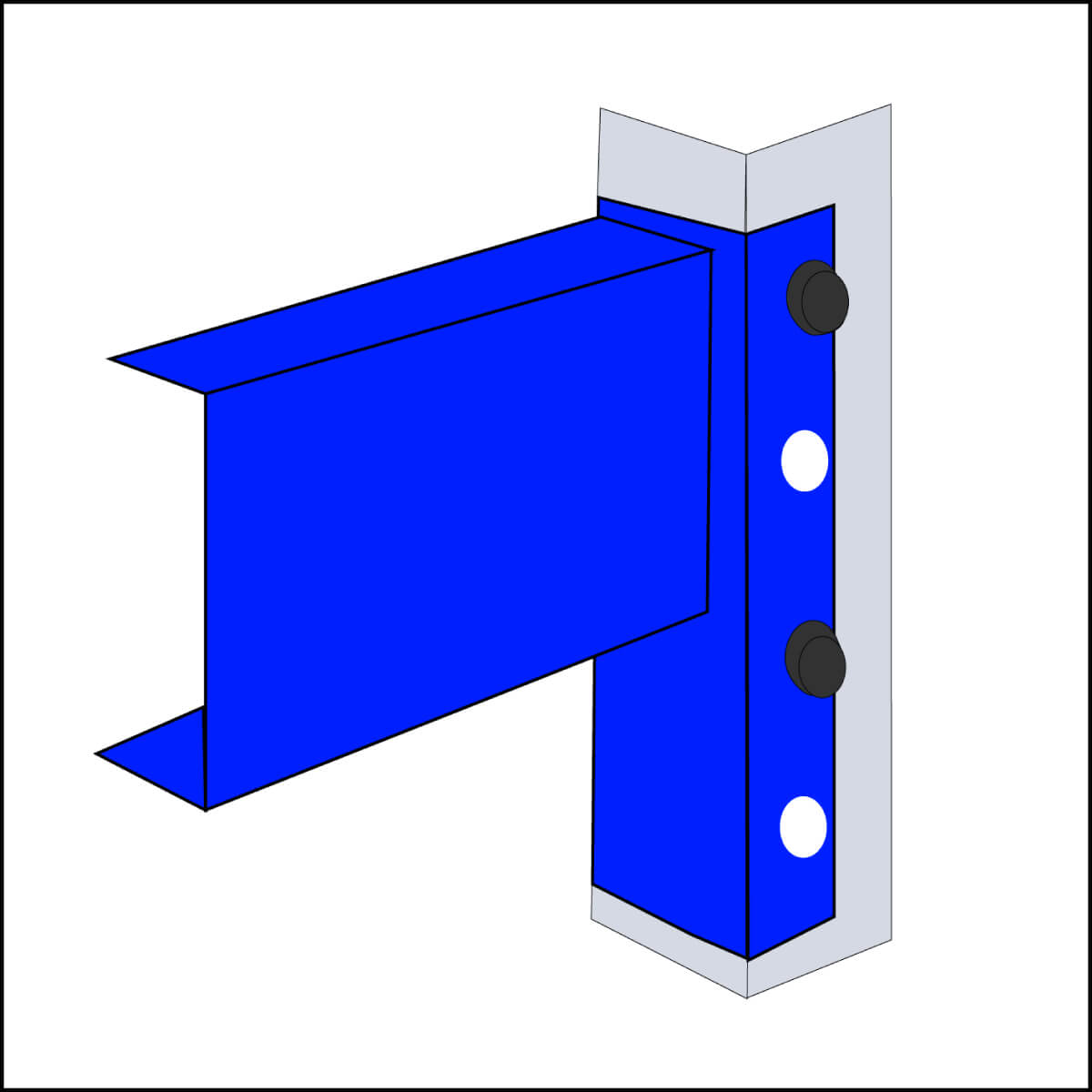

Structural Warehouse Pallet Racking

Structural Steel Pallet Rack systems are typically utilized where heavyweight capacity is required for the product storage, or to eliminate constant rack damage in high-volume applications. Frame-to-beam bolted connections are typically adjustable on 2 or 3-inch center-to-center increments, which allow for versatility with your loading applications.

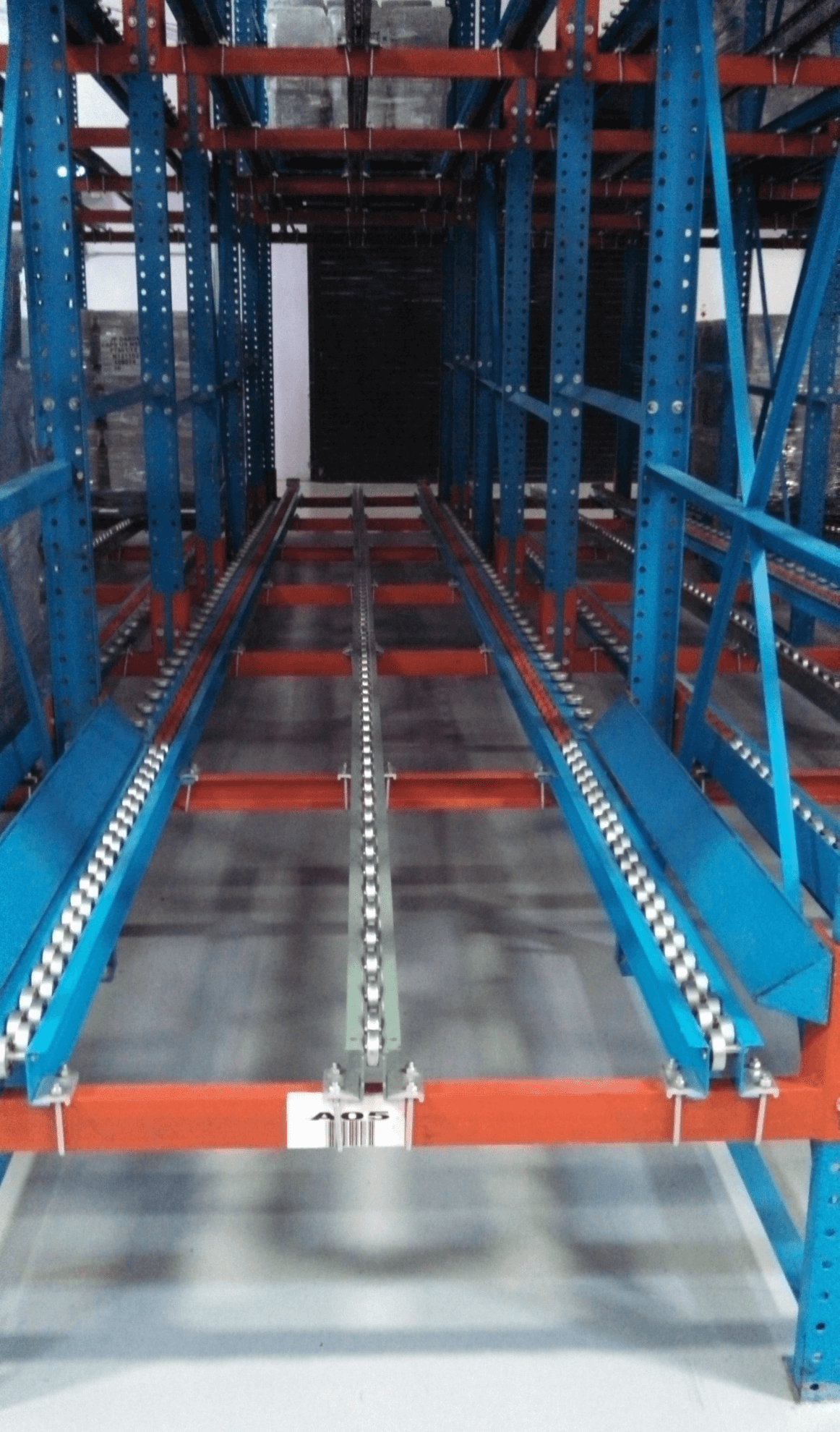

Gravity Flow Rack

Gravity flow storage systems consist of two elements: a static rack structure and dynamic flow rails. The flow rails are a track & heavy-duty roller system set at an incline along the depth of the rack. Pallet loads move along the rails by gravity from the loading end (typically the back) to the unloading end (typically the front).

Each flow lane includes self-energized speed controllers (brakes) to control the speed of movement within each lane. As a pallet of product is removed, the loads behind it move forward to the unloading position. Gravity flow solutions in warehouse pallet racking systems are generally utilized where storage density and inventory rotation (first-in and first-out) are priorities.

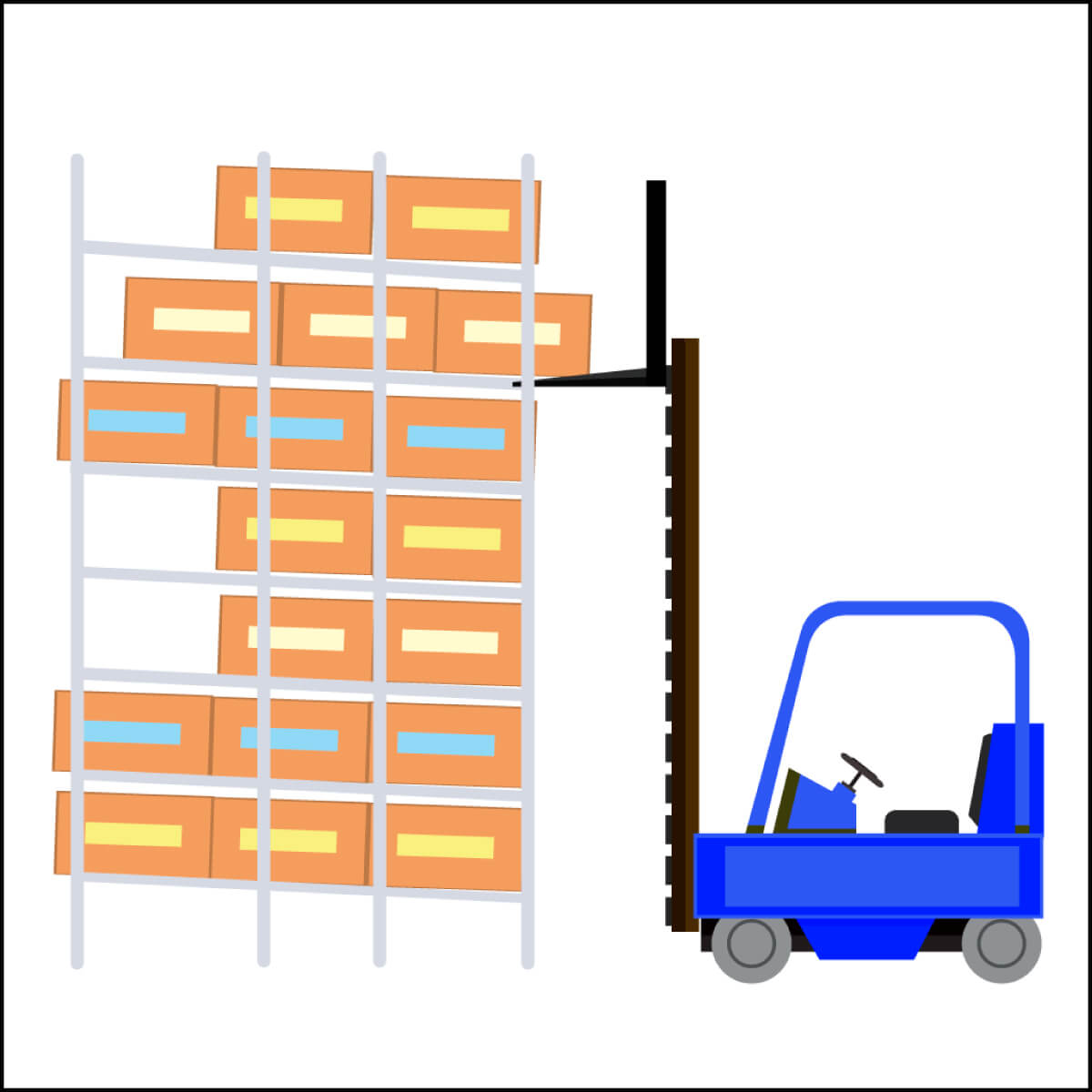

Drive-In Rack

Drive-In Rack systems allow a lift truck operator to enter the rack from one side, loading from bottom-to-top, and then back-to-front. Drive-in systems typically allow entry from a single aisle with a first-in, last-out arrangement for your product.

Drive-in rack storage systems provide the ability to store large quantities of similar loads, maximizing cubic storage utilization in a smaller area.

Push-Back Rack

Push-back Storage Rack Systems are a warehouse pallet racking application that uses mobile carts and rails on a static frame and beam system.

Pallets of products are placed on nested carts riding on inclined rails. Each pallet is pushed back by subsequent pallet loading, exposing the next cart. The reverse happens when removing product; the front pallet is removed, allowing the pallets on carts behind it to roll gently to the front of the system.

The pallet placement and retrieval processes are simple, utilizing standard lift trucks in most cases. Pushback rack systems allow you to store pallets 2 to 6 deep in a dense, no-aisle configuration while allowing for greater selectivity and floor area utilization.

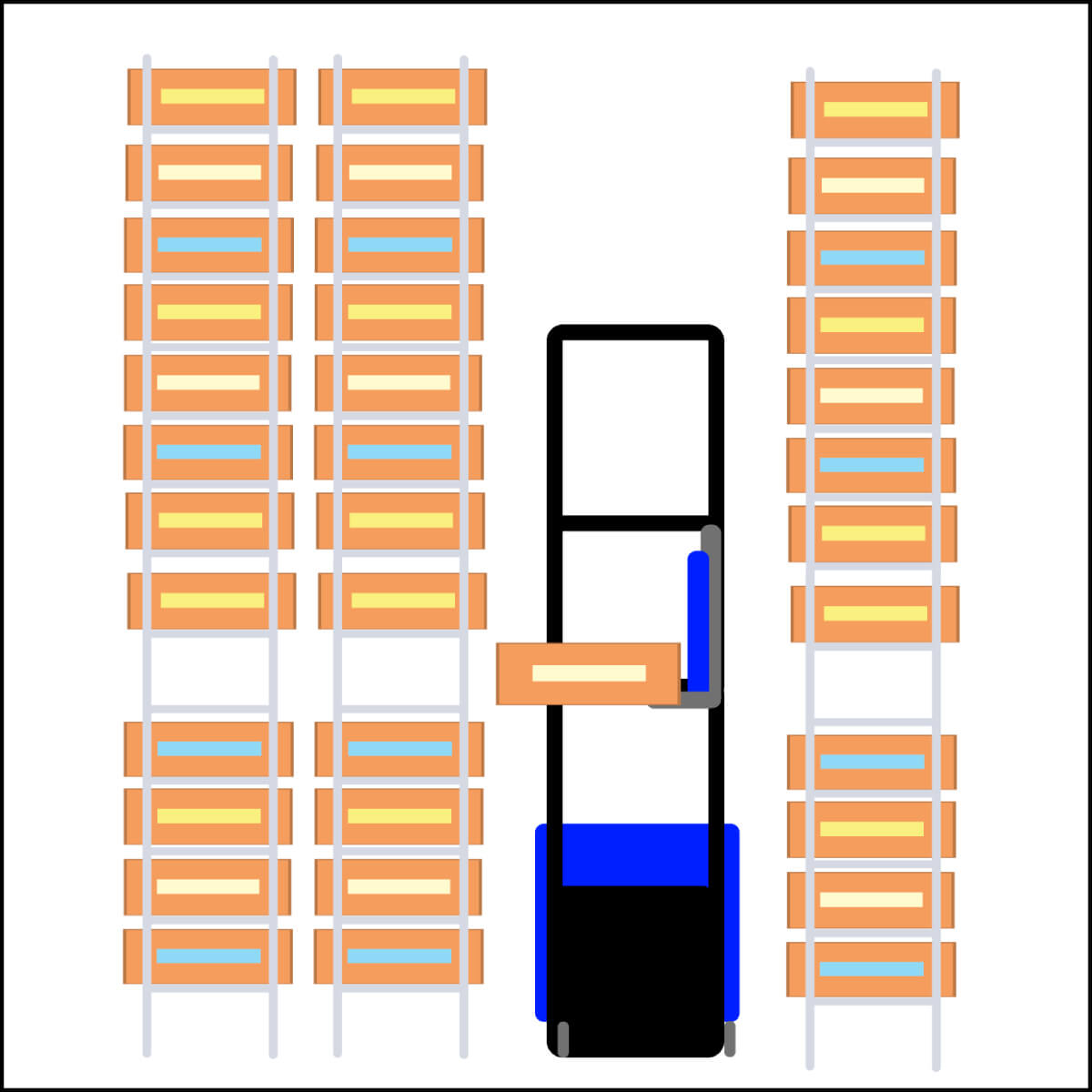

Narrow-aisle systems

Narrow aisle racking provides optimum use of floor area and height while permitting individual access to all pallets (100% selectivity). Specially designed narrow-aisle fork trucks are generally required to maneuver in this type of storage system. Wire guidance or floor mounted guide rails are a must for the safe operation of these warehouse pallet racking systems.

Cantilever Racks

Cantilever racks are ideal for storing long, odd-shaped and unwieldy items in the same storage system. Typical storage applications consist of lumber, pipe storage, and furniture.

We can provide all the warehouse pallet racking storage solutions you need. Get a free quote now and discover just how easy it is to organize your storage layouts.