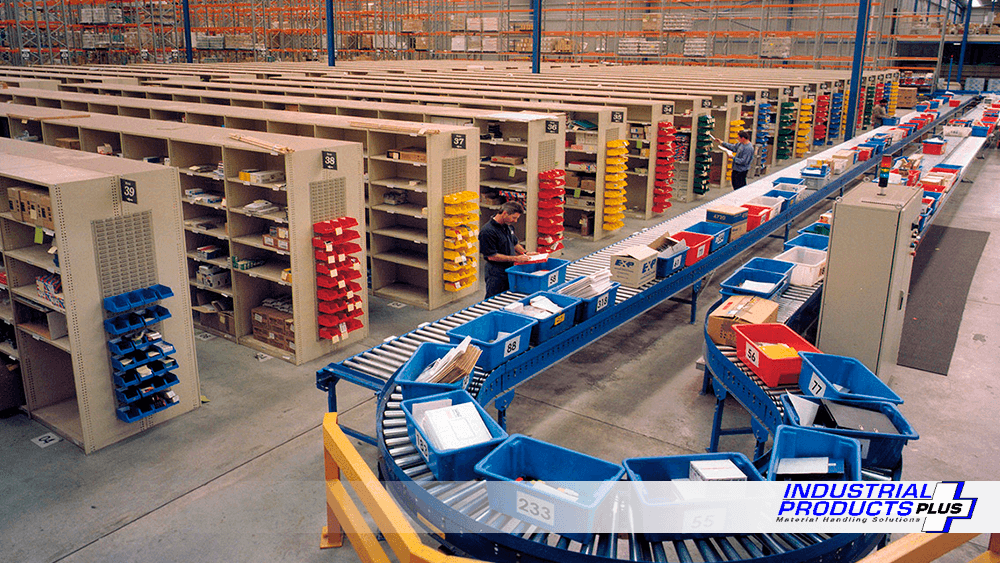

Benefits of having a conveyor system in your warehouse

Gravity conveyor systems provide an effective and efficient method for handling materials in your warehouse, including sorting products and distributing items. Gravity roller conveyors are vital in a wide range of industries and applications such as production assembly, order fulfillment, receiving, processing, and loading docks.

They not only increase warehouse productivity but also improve workflow. Gravity roller conveyors are non-powered, making them a cost-effective solution for material handling industries as they don’t rely on powered systems.

These conveyors rely on the force of gravity and weight of the product to keep pallets moving from one designated station to their final destination. Generally, contractors position gravity roller conveyors minimally sloped to flow with gravity or flat for push-assisted applications.

Advantages of gravity conveyor systems

Due to their cost-effectiveness and simple design, gravity roller conveyors offer various industries numerous benefits. These include:

1. Minimal investment

Gravity roller conveyors have a low cost compared to other types of conveyor systems. This is because they rely solely on gravity, so there’s no need for expensive motors. Additionally, they’re easy to install and operate, keeping expenses down while still optimizing your warehouse operations.

2. Versatile

These conveyors can be installed in numerous locations with different specifications to suit your company’s needs. They come in a wide range of sizes, lengths, widths, and heights, allowing for complete customization. This way, you can get a conveyor that can handle your warehouse’s operations.

3. Flexible

These conveyor systems are manufactured with various components such as rollers, wheels, and chutes and from a wide range of materials, making them suitable for all types of loads. Hence, you can use them for a multitude of material handling solutions, allowing maximum flexibility.

4. Efficiency

Gravity roller conveyors transport materials in a safe, simple, and efficient manner.

5. All galvanized available

These conveyor systems can be galvanized with a protective layer to prevent rusting, extend their life span, and increase their durability. This makes them safe for food and beverage motors.

6. Low maintenance

The rollers in a gravity conveyor system don’t collect debris, ensuring you don’t have to worry about hang-ups.

7. Fast delivery

Disruption in processing and manufacturing can delay your projects and affect your bottom line. Ordering a gravity conveyor systems can normally be delivered faster than other forms of warehouse systems and in a manner that minimizes disruptions to your operations.

Need gravity conveyor systems?

Find the right conveyor solutions for your operations. Call IPP and get a free quote for Warehouse and Material Handling Solutions.